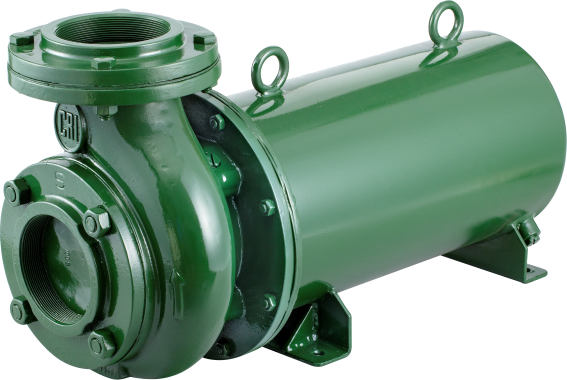

HORIZONTAL OPENWELL SUBMERSIBLE PUMPS

The CSM series of CRI’s Openwell Submersible Pumps are specially designed water-lubricated bearings that are used to withstand the axial thrust loads with minimum wear and tear. CRI’s Submersible pumps offer exceptional value and reliable performance with the double-side carbon pads, which facilitate not only higher wear resistance but also negligible suction and priming problems. Ideal for offering functionality under vast water pressure fluctuations, CRI brings a product that uses significantly less power, as the fluid they pump is pushed and not pulled.

Applications

- Industries

- Agricultural

- Hotels

- Apartments

Key Features

- Heavy cooling design.

- High cooling motor.

- Wide voltage operation.

- No need for a pump house.

- No suction and priming problem.

- Vast applications: irrigation, agriculture, domestic, industrial, garden, rural water supply.

All you need to know about – Horizontal Openwell Submersible Pumps (CSM Series)

Specifications

| Power Range | 2.2 kW – 15 kW |

| Speed | 2900 rpm |

| Version | Single Phase – 200-240V; Three Phase – 380-415V, 50Hz AC Supply |

| Maximum Total Head | 153 metre |

| Maximum Flow Rate | 54 lps |

| Degree of Protection | IP 58 |

| Degree of Rotation | Electrically Reversible |

| Method of Starting | Direct On Line (D.O.L), Star Delta (SD) |

| Type of Duty | 50, 65, 80, 100 & 125 mm |

| Maximum Starts Per Hour | 10 times |

Material of Construction

| Part Name | Material |

|---|---|

| Rear Cover / Bracket | Cast Iron |

| Stator Shell | Cast Iron |

| Shaft | SS 410 / EN – 8 |

| Impeller | Cast Iron / SS 410 / Bronze |

| Pump Casting | Cast Iron |

| Shaft Seal | Nitrile Butyl Rubber |

| Thrust Assembly | SS 420 with Graphite Carbon |

| Diaphragm | High Nitrile Butyl Rubber |

| Journal Bearings | LTB – 4 / LTB – 5 / Carbon |

Applications

- Industries

- Agricultural

- Hotels

- Apartments

Key Features

- Heavy cooling design.

- High cooling motor.

- Wide voltage operation.

- No need for a pump house.

- No suction and priming problem.

- Vast applications: irrigation, agriculture, domestic, industrial, garden, rural water supply.

All you need to know about – Horizontal Openwell Submersible Pumps (Plano Series)

Specifications

| Power Range | 0.37 kW – 1.5 kW (0.5HP – 2HP) |

| Speed | 2880 RPM |

| Version | Single Phase 220 – 240 V, 50Hz, A.C. Supply |

| Maximum Total Head | Up to 45 metre |

| Maximum Flow Rate | Up to 8.5 lps (30.6 m³/hr) |

| Type of Duty | S1 (Continuous) |

Material of Construction

| Part Name | Material |

|---|---|

| Rear cover / Bracket | Cast iron |

| Stator Shell | Cast Iron |

| Shaft | SS 410 / EN – 8 |

| Impeller | Cast Iron / SS 410 / Bronze |

| Pump Casting | Cast Iron |

| Shaft Seal | Nitrile Butyl Rubber |

| Thrust assembly | SS 420 with graphite carbon |

| Diaphragm | High Nitrile Butyl rubber |

| Journal Bearings | LTB – 4 / LTB – 5 / Carbon |

The CSM series of CRI’s Openwell Submersible Pumps are specially designed water-lubricated bearings that are used to withstand the axial thrust loads with minimum wear and tear. CRI’s Submersible pumps offer exceptional value and reliable performance with the double-side carbon pads, which facilitate not only higher wear resistance but also negligible suction and priming problems. Ideal for offering functionality under vast water pressure fluctuations, CRI brings a product that uses significantly less power, as the fluid they pump is pushed and not pulled.

Applications

- Industries

- Agricultural

- Hotels

- Apartments

Key Features

- Heavy cooling design.

- High cooling motor.

- Wide voltage operation.

- No need for a pump house.

- No suction and priming problem.

- Vast applications: irrigation, agriculture, domestic, industrial, garden, rural water supply.

All you need to know about – Horizontal Openwell Submersible Pumps (CSM Series)

Specifications

| Power Range | 2.2 kW – 15 kW |

| Speed | 2900 rpm |

| Version | Single Phase – 200-240V; Three Phase – 380-415V, 50Hz AC Supply |

| Maximum Total Head | 153 metre |

| Maximum Flow Rate | 54 lps |

| Degree of Protection | IP 58 |

| Degree of Rotation | Electrically Reversible |

| Method of Starting | Direct On Line (D.O.L), Star Delta (SD) |

| Type of Duty | 50, 65, 80, 100 & 125 mm |

| Maximum Starts Per Hour | 10 times |

Material of Construction

| Part Name | Material |

|---|---|

| Rear Cover / Bracket | Cast Iron |

| Stator Shell | Cast Iron |

| Shaft | SS 410 / EN – 8 |

| Impeller | Cast Iron / SS 410 / Bronze |

| Pump Casting | Cast Iron |

| Shaft Seal | Nitrile Butyl Rubber |

| Thrust Assembly | SS 420 with Graphite Carbon |

| Diaphragm | High Nitrile Butyl Rubber |

| Journal Bearings | LTB – 4 / LTB – 5 / Carbon |

Applications

- Industries

- Agricultural

- Hotels

- Apartments

Key Features

- Heavy cooling design.

- High cooling motor.

- Wide voltage operation.

- No need for a pump house.

- No suction and priming problem.

- Vast applications: irrigation, agriculture, domestic, industrial, garden, rural water supply.

All you need to know about – Horizontal Openwell Submersible Pumps (Plano Series)

Specifications

| Power Range | 0.37 kW – 1.5 kW (0.5HP – 2HP) |

| Speed | 2880 RPM |

| Version | Single Phase 220 – 240 V, 50Hz, A.C. Supply |

| Maximum Total Head | Up to 45 metre |

| Maximum Flow Rate | Up to 8.5 lps (30.6 m³/hr) |

| Type of Duty | S1 (Continuous) |

Material of Construction

| Part Name | Material |

|---|---|

| Rear cover / Bracket | Cast iron |

| Stator Shell | Cast Iron |

| Shaft | SS 410 / EN – 8 |

| Impeller | Cast Iron / SS 410 / Bronze |

| Pump Casting | Cast Iron |

| Shaft Seal | Nitrile Butyl Rubber |

| Thrust assembly | SS 420 with graphite carbon |

| Diaphragm | High Nitrile Butyl rubber |

| Journal Bearings | LTB – 4 / LTB – 5 / Carbon |